Brand Insights from Kemin

Wet pet food is a popular choice among pet owners, with more than 6.5 billion kg sold in 20221. Pet owners often see wet pet food as a more premium option than traditional dry kibble diets. They expect their preferred wet pet food brand to be palatable to their pets and have the same appealing aroma, color, and texture every time they open the can or pouch. Consistency in these attributes is particularly important for pet food manufacturers to maintain their brand image. Flavor, aroma, color, and texture can be affected by key pet food production parameters, including processing conditions, pH, grind size, and thickeners.

THE RIGHT TEXTURE

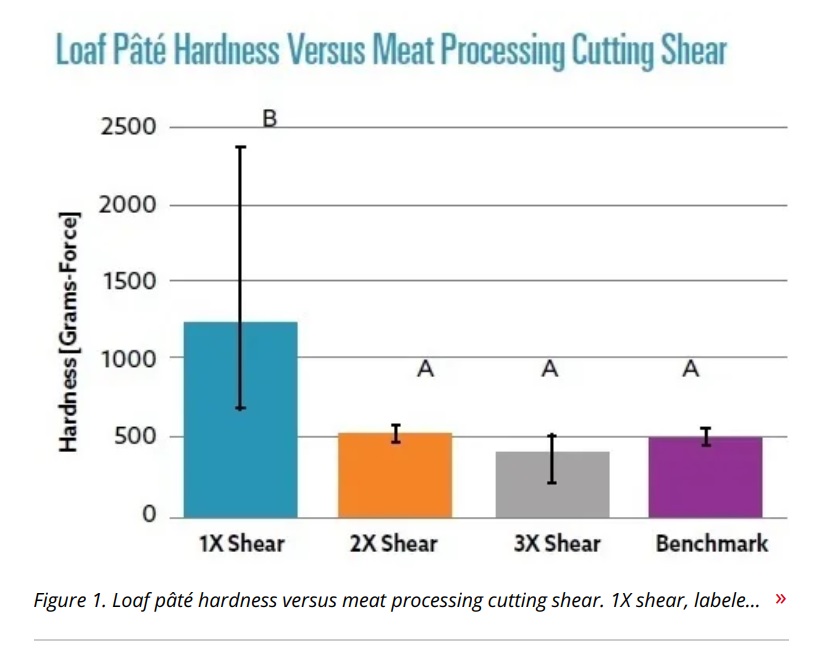

Although each wet pet meat dough manufacturing process may be unique, it has been observed that the meat grind and quality of disintegration affect the texture or firmness of the loaf pâté. It has been observed that cats prefer to eat diets with a softer loaf pâté texture compared to a harder one. Pet parents may also prefer the look of a soft pâté bread as opposed to a hard, crunchy one2. Loaf pâté quality is a measure Kemin measures in diets produced at their Wet Pet Food Pilot Plant. Texture Test by Kemi3 A texture analyzer with a ball probe can simulate the feel of meat in an animal’s mouth and on their model diet. Diets with different meat cutting shears were produced at the Kemin Wet Pet Food Pilot Plant and compared to a commercially available Turkey and Giblet Loaf Pâté diet using Tukey Honest Square Differences statistical analysis, with a p-value of less than 0.05 to distinguish texture differences. The Turkey and Giblet Loaf Pâté recipe with a little grinding of meat and cutting shears has a firmer loaf pâté than twice and three times as much shear. [Figure 1]. Compared to the desired texture of the benchmark loaf pâté diet, it was observed that too little cutting shear created a stiffer loaf pâté. Using twice and three times more cutting shear produced a similar firmness texture to the benchmark loaf pâté.

ACHIEVING THE IDEAL “LOOK”

Just as cooking a steak or chicken breast releases juices, meats in a wet pet food release water during sterilization cooking through the retort process. Meat scientists refer to these juices as weeping, syneresis, or so-called moisture. Loaf pâté diets sometimes have an extra liquid weep, which can be thinned with gravy or gel. Excessive crying can affect consumer perception, as some consumers view high-quality wet pet diets as having a thick liquid like gravy or gel. Often thickeners such as starches, gums, and proteins are added to diets and special processing is used to enhance digestible proteins and reduce liquid weeping. Literature from Kansas State University confirms that wet pet diets containing only the ingredients necessary for complete and balanced nutrition can be too thin to fill cans quickly, have sedimentation challenges, and release too much liquid after cooking sterilization.

The type and amount of thickeners must be balanced to achieve the correct “look”, including the correct amount and thickness of liquid in a wet diet. Both “Thick to Thin” and “Thin to Thick” are required.

“Thick to Thin” Guar gum is a popular ingredient to add to nutritious wet pet meat dough to thicken it, maintain a homogenous mixture, and fill cans quickly. After cooking sterilization, wet pet diets with added guar gum resemble diets without guar gum. In other words, the viscosity and thickness provided by guar gum helps in cooking but not to maintain a thick liquid after cooking.

“Thin to Thick” Other thickeners, gums, and proteins are added to the nutritious wet mass of pet meat to enhance their properties after cooking sterilization. These gums are considered “Thin to Thick” ingredients, they include kappa carrageenan, xanthan gum, and locust bean gum. These thickeners offer some viscosity before the cooking step but have been observed to thicken the remaining liquid and significantly reduce the liquid after cooking sterilization.

Read the full article at customercravings.com